Trick Advantages of Using a Membrane Switch in Industrial Applications

Exactly How Membrane Layer Changes Contribute to the Toughness of Electronic Control Panels

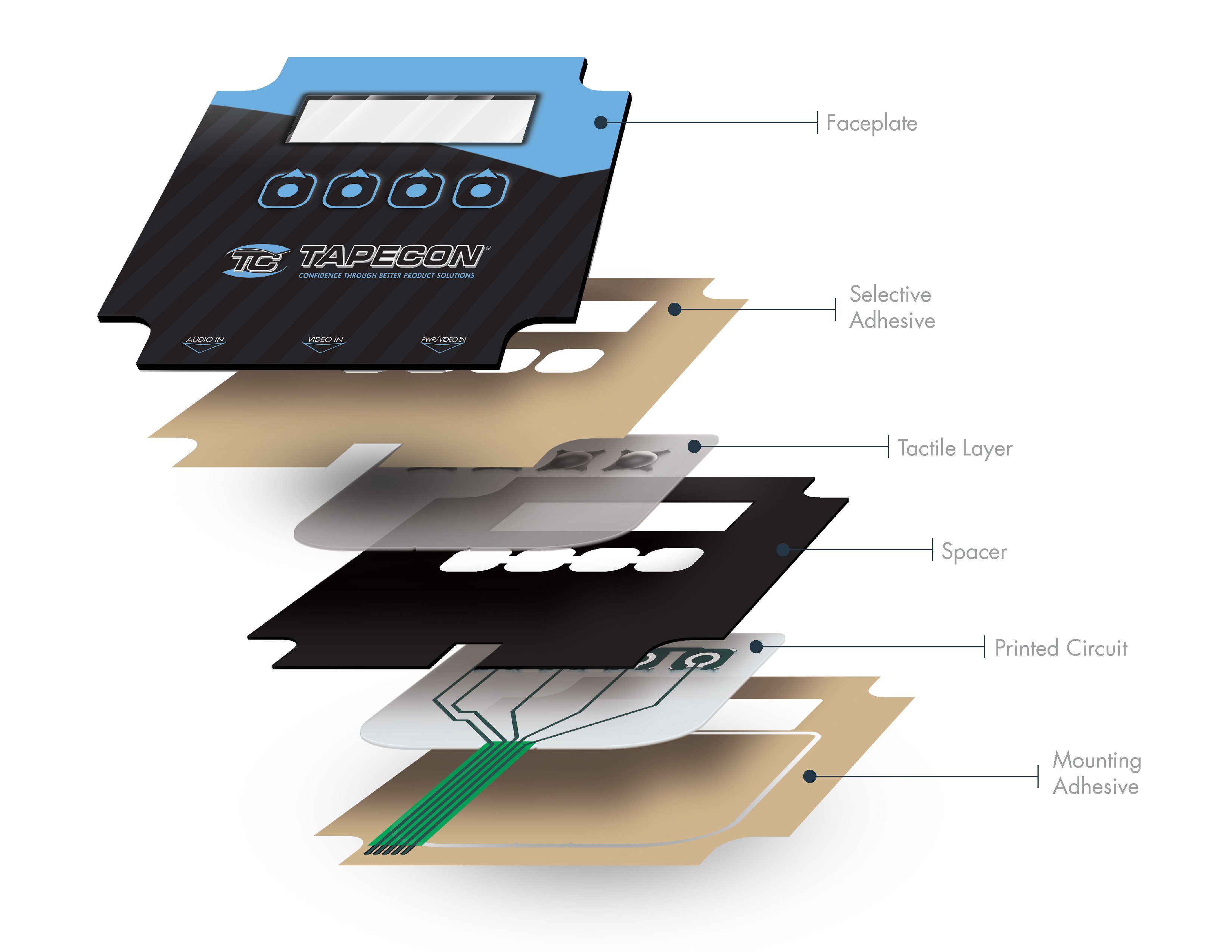

Membrane layer buttons play a crucial duty in enhancing the sturdiness of electronic control panels, primarily with their multi-layered building and construction which provides effective security versus environmental factors such as moisture and dust. This layout not only lessens the threat of circuit damages and corrosion but likewise promotes ease of upkeep because of its seamless surface. The absence of relocating components dramatically reduces the likelihood of mechanical failures, making membrane switches perfect for requiring applications. Nonetheless, the ramifications of these features extend past mere security, elevating concerns about their broader effect on performance and customer experience.

Definition of Membrane Layer Buttons

Membrane layer switches are developed to be thin and lightweight, making them suitable for applications where area is limited. They can be made in numerous shapes, sizes, and shades, providing flexibility in layout that satisfies aesthetic and practical requirements. Additionally, membrane layer switches can incorporate numerous modern technologies, such as tactile responses and LED signs, improving individual experience.

As a result of their building and construction, membrane layer buttons are often resistant to dust, moisture, and general wear, adding to their toughness sought after settings. Their smooth design not just assists in simple cleansing yet additionally decreases the threat of mechanical failing, making them a favored option for producers seeking reputable user interfaces in their electronic control board.

Protection Versus Ecological Factors

The design of membrane layer switches inherently supplies a level of protection versus numerous ecological aspects, which is important for maintaining capability in challenging problems - Membrane Switch. These buttons are typically created with layers of adaptable materials that secure inner elements from moisture, dirt, and impurities. By encapsulating the circuitry, membrane layer changes minimize the threat of short circuits and rust, which can considerably impair efficiency

Furthermore, the use of durable adhesives and sealants throughout production improves their resistance to ecological obstacles. Membrane switches can withstand direct exposure to chemicals and solvents, making them suitable for sectors such as food handling and healthcare, where health and sanitation are extremely important. Their smooth surface area style also stops the accumulation of dust and bacteria, assisting in easier cleansing and maintenance.

Temperature level fluctuations are one more ecological concern, and membrane switches are crafted to wikipedia reference function efficiently across a vast array of temperature levels (Membrane Switch). This versatility makes certain that control panels stay functional in numerous setups, from commercial environments to consumer electronic devices

Influence On User Interaction

Individual interaction with electronic control panels is considerably influenced by the design and performance of membrane layer switches. These switches offer a tactile interface that improves the total user experience, permitting user-friendly navigating and control. Their receptive nature ensures that users get immediate responses upon activation, which is critical for jobs needing precision and effectiveness.

Additionally, the smooth surface area of membrane layer switches over promotes easy cleansing and maintenance, promoting user confidence in the dependability of the interface. This cleanliness is particularly vital in environments where hygiene is paramount, such as medical or food processing settings. Additionally, the compact and lightweight layout of membrane switches adds to the visual appeal of control panels, motivating user interaction with a contemporary and streamlined look.

Additionally, the assimilation of visual elements, such as printed icons and backlighting, helps customers swiftly determine features, reducing the learning curve related to new equipment. Therefore, customers can operate devices better, resulting in increased performance and complete satisfaction. In recap, membrane layer switches play an essential function in improving user interaction by integrating functionality, aesthetics, and ease of usage, eventually causing improved operational performance.

Style Flexibility and Personalization

Design flexibility and modification are essential facets of membrane buttons, enabling makers to customize electronic control board to certain applications and individual needs. This flexibility permits the assimilation of different layout aspects, such as shades, graphics, and appearances, which can improve the aesthetic charm and individual interaction of the control panel.

Membrane layer switches can be personalized in shapes and size, accommodating a vast array of devices and applications, from industrial equipment to customer electronics. This flexibility makes certain that manufacturers can produce instinctive user interfaces that line up with user expectations and functional requirements. Additionally, the capability to integrate special attributes such as backlighting or tactile feedback further boosts use, enabling a more interactive experience.

Additionally, the production process for membrane layer changes sustains the fast prototyping of styles, making it possible for producers to iterate and improve their concepts promptly. This ability not only speeds up the growth timeline but likewise makes sure that the last item fulfills details practical and visual criteria.

Cost-Effectiveness and Long Life

Cost-effectiveness and long life are substantial benefits of membrane buttons, making them an appealing choice for makers and end-users alike. These switches are generally cheaper to create than standard mechanical buttons, primarily due to their streamlined manufacturing procedures and the lowered number of components called for. This cost advantage extends not just to first manufacturing but likewise to lasting operational expenses, as membrane layer buttons commonly call for less maintenance and have a reduced failing rate.

Furthermore, the durability of membrane layer changes contributes to their general value. Built from sturdy products, they are resistant to ecological elements such as moisture, dust, and chemicals, which can lead to premature wear in other button kinds. The absence of moving parts decreases mechanical failure, allowing membrane changes to keep performance over expanded durations.

This resilience is especially helpful in applications needing consistent performance under demanding problems, such as clinical gadgets and his comment is here commercial equipment. Eventually, the combination of cost-effectiveness and long life makes membrane switches an economically viable selection pop over to this site for manufacturers, supplying trustworthy services that withstand the test of time while maximizing budgetary factors to consider.

Conclusion

In final thought, membrane layer buttons significantly boost the sturdiness of digital control panels through their robust construction and safety functions - Membrane Switch. Overall, membrane switches represent a reliable and cost-efficient option for enhancing the durability and performance of digital control systems.